API 653 - Tank Inspection, Repair, Alteration, and Reconstruction

AISL tank inspection program ensures that the minimum requirements for maintaining the integrity of tanks after they have been placed in service are met and addresses inspection, repair, alteration, relocation, and reconstruction.

API 510 - Pressure Vessel Inspection Code: Maintenance Inspection, Rating, Repair, and Alteration

AISL vessel ensures that the minimum requirements for maintaining the integrity of vessels after they have been placed in service are met and technically qualified to maintain, inspect, repair, alter, or rerate pressure vessels. Our inspectors are qualified to this code.

API 570 - Piping Inspection Code: In-service Inspection, Rating, Repair, and Alteration of Piping Systems

AISL piping inspection program covers inspection, rating, repair, and alteration procedures for metallic and fiberglass reinforced plastic (FRP) piping systems and their associated pressure relieving devices. AISL ensures that piping placed in-service, minimum requirements for maintaining the integrity of the operating systems are met.

AWS-CWI- Certified welding inspector.

AISL welding services ensures that our AWS Certified Welding Inspector, is responsible for inspecting weld quality, workmanship, and conformance before, during and after welding, to ensure specifications are met or surpassed.

Lifting equipment inspection

AISL lifting equipment program consist of inspectors, competent in knowledge, skill, and experience in performing in-house inspections to the latest OSH-A and ASME mobile crane and overhead cranes standards.

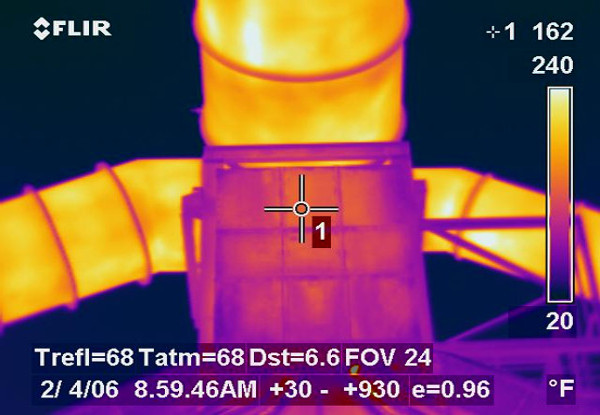

NDE - Nondestructive examinations

AISL NDE program ensures that requirements and methods for nondestructive examination meet the required Code Sections. These nondestructive examination methods are intended to detect surface and internal discontinuities in materials, welds, and fabricated parts and components. They include liquid penetrant examination, magnetic particle examination, visual examination, thermography, and leak testing.